Advantages and Disadvantages of HVOF Coating

High Velocity Oxygen Fuel (HVOF) represents a cutting-edge thermal spray technology that has transformed the coating industry. By propelling molten or semi-molten materials at incredible speeds onto various substrates, HVOF is celebrated for its ability to deliver superior coating properties across a wide range of industrial applications. As a result, HVOF has become the preferred method for producing dense, durable coatings on diverse surfaces.

: 12.06.2024

: 12.06.2024

What is HVOF Coating?

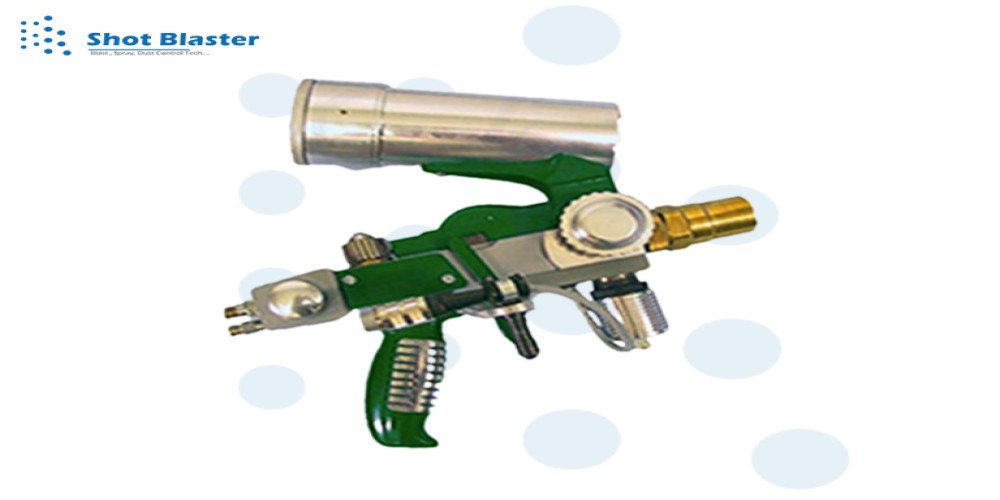

The HVOF Coating strategies are utilized to improve the surface possessions of ingredients. HVOF Coating process, a lower price or weightless material can be formulated with an operational & elevated achieving surface. Hvof Spray Gun approaches can be utilized to improve also restore injured elements.

HVOF gun is a thermal spray gun system engaging the combustion of gases. HVOF spraying merges velocities as far as 700 m/s & more elevated with reasonable temperatures. HVOF Coating process delivers a remarkably thick coating (> 97%). Deposit speeds are as far as 9 kg/hour, & coating consistencies vary from 0.05 - 1 mm. The HVOF process utilizes fuel gas like propane, propylene, & natural gas.

For more info about Flame Spray Gun visit our website.

Advantages of HVOF Coating

Particle velocity is very important in the thermal spray process, as the more elevated the velocity, the more elevated the adhesive stability, & the more down porosity. This is because particles have less time to cool down at elevated velocities. The HVOF process is designed around producing high velocities & this confers many of the advantages that HVOF technique has over further thermal spray techniques, which include:

- Better constant & efficient bit heating, due to the high turbulence encountered by the bits

- Broadly quicker orientation time in flight due to heightened particle speeds.

- Quick particle orientation time in ambient air, once the jet & particles escape the HVOF gun, which results in more inferior surface oxidation of particles.

- Descending flame temperature resembled plasma spraying.

- More inferior maximum particle temperatures corresponded to further processes.

- Lower cost & ease of usage corresponded to further processes.

- Wider coatings with arc spray gun & plasma spraying can be assembled.

Disadvantages of HVOF Coating

- The amount of heat content in the HVOF system is extremely elevated, so overheating of the substrate is quite likely. Hence additional cooling of the substrate is essential, & cooling with liquid CO2 is now a prototype with the new HVOF process.

- Masking of the part is still a great problem as only mechanical masking is effective. It is very hard and time-consuming to design an effective mask for a complex component with areas, which do not require deposition.

For more information about thermal spray wire Visit our website.

Benefits of using the HVOF coatings

- More elevated density (Lower porosity) due to More elevated impact energy.

- Improved corrosion barrier caused by Less porosity.

- More elevated hardness ratings owing to More suitable bonding, less degradation, and denser coatings.

- Improved wear resistance due to Harder coating.

- Higher bond & cohesive force are assignable to Improved bit bonding.

- Lower oxide range due to Minor in-flight orientation time to air.

- Fewer unmelted particle content as a consequence of More useful particle heating.

- More awesome chemistry & phase retention reasons Decreased time at more elevated temperatures.

- Thicker coatings due to Less residual stress.

- The smoother as-sprayed surface main reason for More elevated impact energies.

For more details about metalizing gun visits our website.

All Blogs