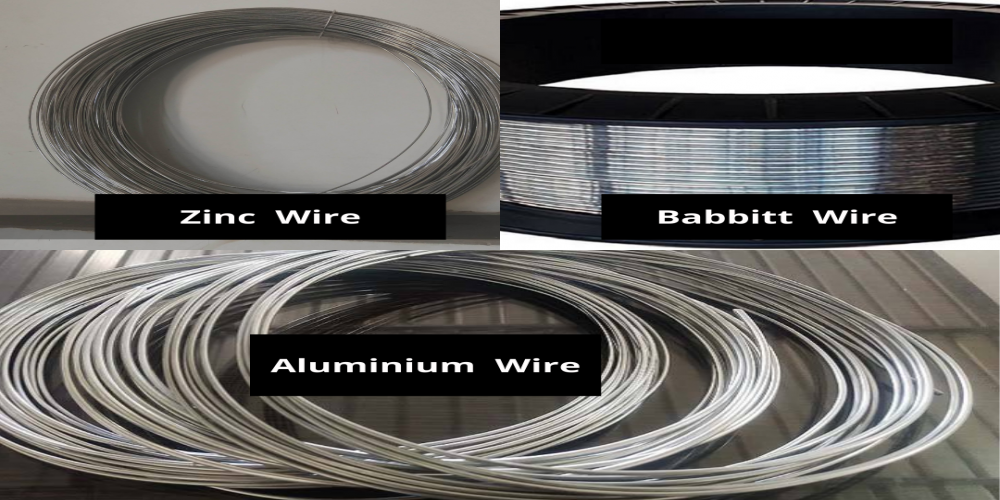

Types of Metalizing Wire

Metalizing wire uses in a thermal spray gun to provide protecting coating layer at the substrate. The coating is furnished to increase the existence of substrate use in different applications and provide safety from rust, oxidation to the substrate utilized in sea and open environment areas.

: 31.07.2023

: 31.07.2023

Types of Metalizing Wire

Metalizing Wire used inside the thermal spray gun for the coating process. Coating affords over the substrate with a distinctive approach. Thermal spraying is accomplished to increase the life of the substrate and save it from corrosion in even the hardest situation. The choice of metalizing wire inside the thermal spray is based totally on the utility of the substrate on which coating to be executed. Metalizing wires are utilized in natural form as well as in alloy form also.

Zinc Metalizing Wire

It is the best material choice for corrosion protection in each atmospheric and marine environment. Using the electric arc spray gun and combustion Zinc Spray Gun, Wire Flame Spray Gun, Zinc Metalizing wire Coating of those materials acts as sacrificial anodes, galvanically protecting alloy or steel substrates. A long time of fieldwork using these zinc coatings has simply demonstrated that they're a long way more powerful and longer-lasting than warm-dip galvanizing.

Applications of Zinc Metalizing Wire

- Air and drenching erosion security on significant metallic or iron buildings like scaffolds, street hindrances, posts and shafts, seaward designs, and marine designs.

- Climatic erosion safety on steel or iron parts like tanks and gas bottles.

- Zinc wire for the thermal spray gun.

- EMI and RF defensive on plastic.

- Electrical conductance on components like the conductive territories on protectors and capacitor quit covers.

Babbitt Metalizing Wire

They are used within the metal wire for the thermal coating process. The thermal spray uses a wire flame spray gun or an electric arc wire spray process for coating. White metals can be known as Babbitt. These white substances can be anatomy, copper, tin, or lead. Wires have both smooth and hard compositions and that provides perfect low friction resistance and wear resistance.

Applications of Babbitt Metalizing Wire

- Used in high duty mechanical work

- Coating of high-speed mechanical bearing

- In food industries to protect the tank from rust

- A dense Coating layer is required in sliding components

Aluminum Metalizing Wire

It is used in the coating process and drawn to a variety of diameter for use in an arc spray gun and flame spray gun machine. It has useful features that consist of resistance to the atmosphere, chemicals, and corrosion. Aluminum wires are suitable for electric conductors. Aluminum wire coating tends to shape an oxide film that protects it from further attack.

Applications of Aluminum Metalizing Wire

- General industry: Cathode corrosion protection coating on steel structures.

- Aviation: To provide coatings on fiberglass panels for static dispersion & corrosion protection of the outer casings.

- Automotive: Coating on high-temperature corrosion protection on exhaust valves.

- Electronics: Coating over an electrical conductance on components like conductive areas on insulators, capacitor end caps, &varsities.

Copper Metalizing Wire

It is a corrosion-resistant material in a non-oxidizing environment; normally used to provide resistance to impartial atmospheric situations and seawater environments. Copper wire has great electrical and thermal conductivity. They are used within the thermal spray system for healing particularly on copper alloy substrate and in electric programs in which a coating is needed with properly conductivity.

Applications of Copper Metalizing Wire

- Restoration of worn non-ferrous components

- A substrate that requires thermal management or electrical conductivity in the application

- In the Paper and printing industries to resist corrosive inks

- Electrical contacts and ground connectors

- Self-lubricating bearings

Wire Manufacturer’s in India

Blast Room is the best Wire Manufacturers in India. We provide Aluminum Metalizing Wire, Babbitt Metalizing Wire, Zinc Metalizing Wire, and Copper Metalizing Wire, Bronze, Tin and etc, at the best prices in India.

All Blogs